What exactly is meant by the term "die casting" and what are its defining characteristics

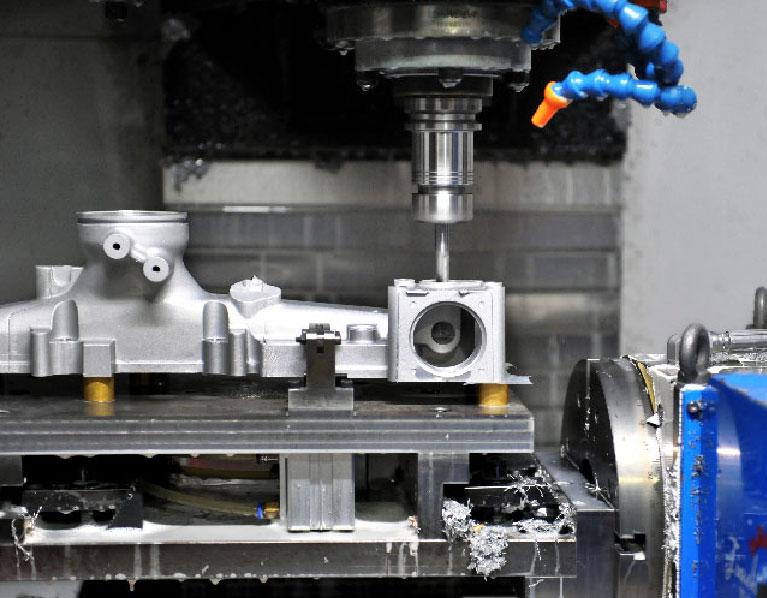

The mold that is used in die casting is referred to as a die casting die, or just die for short. Punch dies are specialized tools that are utilized in the batch processing of materials (metal or non-metal) into the necessary die casting components. Die casting dies are an essential component of die casting. Batch die casting production will be difficult if the die casting dies that are used do not meet the requirements; advanced die casting processes will not be possible if the die casting dies that are used are not advanced. Die casting is a manufacturing process that consists of three distinct components: die casting technology and die casting molds, die casting equipment, and die casting materials.

When compared to other methods of plastic processing and mechanical processing, die casting processing has advantages in terms of both the technical and economic aspects of the manufacturing process.

Die casting is a process that has a high production efficiency, is simple to operate, and is straightforward to mechanize and automate. This is due to the fact that die casting is almost entirely reliant on die casting equipment and die casting dies to complete the processing. The number of strokes of an ordinary press is in the dozens per minute, whereas the number of strokes of a high-speed press is in the hundreds or even more than a thousand per minute, and each die casting press has its own unique number of strokes per minute. During the trip, you will have the opportunity to get a stamped section.

When die casting, the mold guarantees the dimensional and shape accuracy of the stamped parts and, in most cases, does not degrade the surface quality of the stamped materials. Because the life of the mold is generally longer, the parts that are produced by die casting have a consistent quality, are easily interchangeable, and have the "one mold-like" characteristics.

Die casting is able to process components with a wide variety of sizes and complex shapes. These components can be as small as the second hand of a clock or as large as the longitudinal beams of an automobile, covering parts, and so on. In addition, the cold deformation and hardening effect of the material that occurs during the die casting molds process ensures that the strength and stiffness of the stamped parts are increased even further.

Die casting is an industrial process that, in general, does not produce chips and scraps, consumes less material, and does not require additional heating equipment. Die casting is an efficient method of processing that not only saves on materials but also on energy, and as a result, the cost of die cast parts is relatively low. Die casting, on the other hand, requires highly specialized molds because of the nature of the process. When processing a complex part, it is sometimes necessary to use multiple mold sets.

As a result of the high level of precision and stringent technical requirements, forming and mold manufacturing are examples of products that are extremely technology-intensive. Because of this, the benefits of die-casting processing cannot be fully reflected until the production batch of die cast parts is large enough. As a result, better economic benefits can be obtained from the process.